-

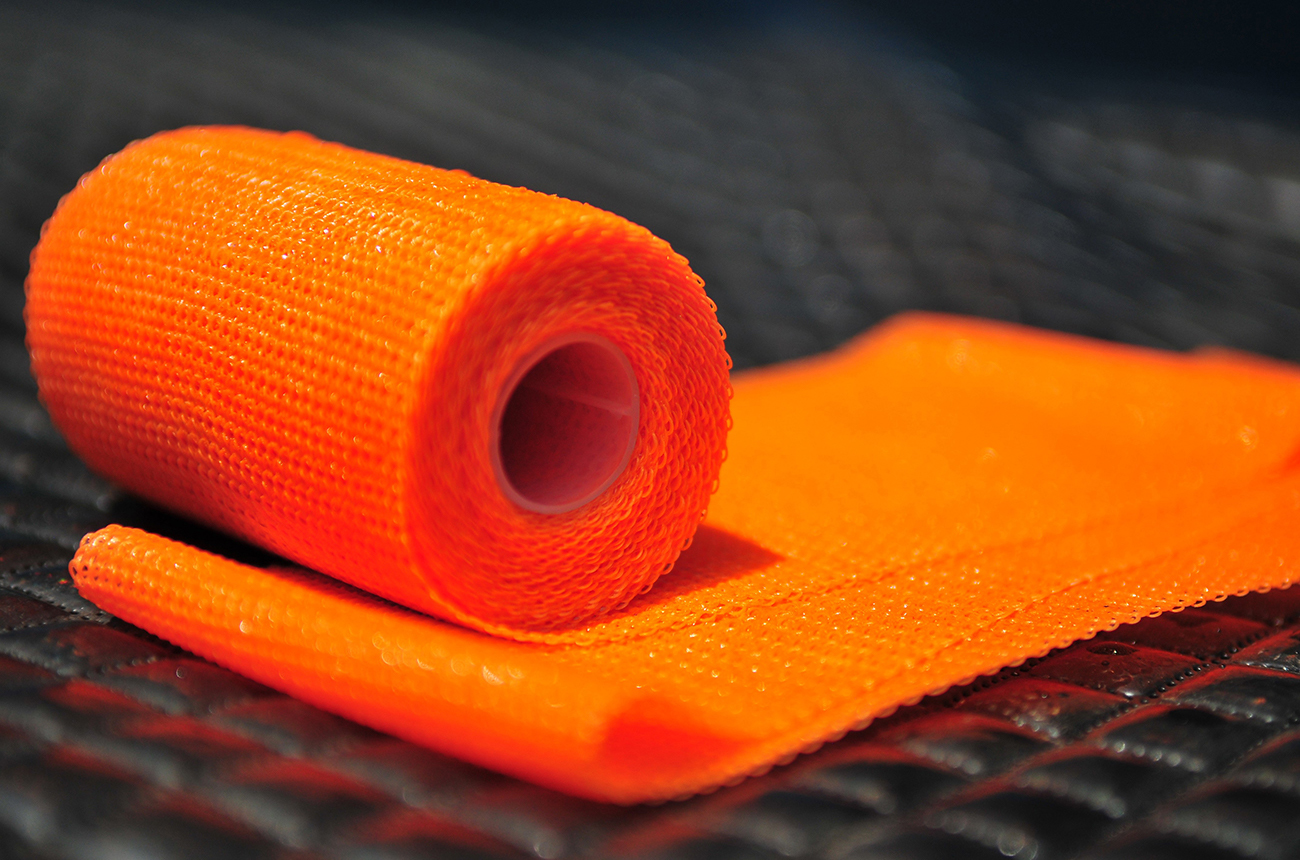

As a medical device for orthopedic use, It is strong enough

-

As a casting materials, it has full adhesion between each fabric

-

A well-fitted moldability

-

2) As a chemical product, it has a stable condition for peak temperature and odor smell

-

Water activated polyurethane resin that does not smear on the glove and it not sticky

-

An excellent coloration without stains

-

Deliveries to global distribution companies in the U.S., Japan